how to test knife hardness|rockwell knife hardness chart : sourcing Steel hardness is measured by the Rockwell C Scale or HRC. Scratch testing is a method you can administer yourself with a kit that contains six files. The files range in hardness from 40. WEBDec 15, 2023. Older versions. Advertisement. Johnny Trigger is a 2D action game where you play as an elite assassin, whose mission it is to kill all the mafiosos he encounters. .

{plog:ftitle_list}

Resultado da Vídeos Pornôs Com Gostosa De Fio Dental. Mostrar 1-32 de 283. 1:31. Morena Gostosa De Fio Dental Vermelho Sentando até gozar dentro! .

You can't determine Rockwell hardness with a scratch test or vice versa. However, the scratch test isn't completely worthless, pass/fail or anything like that. One test is for the resistance to scratching and the other to . Steel hardness is measured by the Rockwell C Scale or HRC. Scratch testing is a method you can administer yourself with a kit that contains six files. The files range in hardness from 40. A classic blade test is a brass rod test where you sharpen a blade then roll the edge on a brass rod. The behavior of the edge (if it deflects and comes back, picks up . The Rockwell Hardness Scale is a standardized measurement system used to determine the hardness or resistance to deformation of a material, especially metals. For kitchen knives, this scale is a crucial indicator of how .

One example is the Brinell hardness test, used to rate and measure metals too coarse to capture a proper reading on the Rockwell system. Another example is the Vickers hardness test, a method crucial for testing and measuring thin . How do you know if a kitchen knife is tough enough to last? It depends on where it falls on the Rockwell Hardness Scale, as explained in this F.N. Sharp guide.

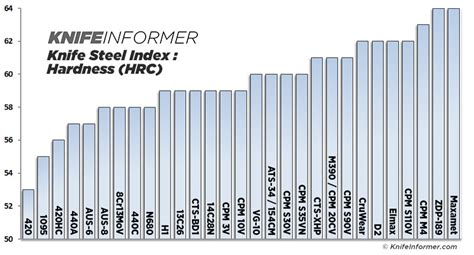

Regardless of its intended use, any good knife should have a hardness rating between 52 HRC and 64 HRC. Super-hard knives are great for kitchen duties where accurate, thin slices must be made regularly. Softer .There stands one element that defines the steel hardness of a knife blade and its ability of edge retention: Rockwell Hardness Number. Most knife manufacturers advertise that their blades conform to a certain hardness number on the .

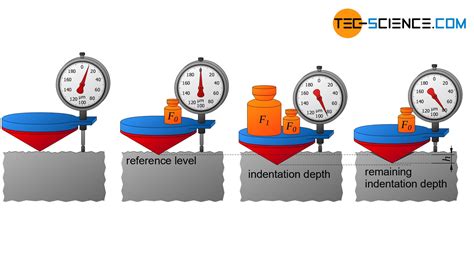

The Rockwell Hardness Scale is a clear way to measure how hard a knife is, which helps keep quality standards high across the business. If you understand this scale, you’ll be able to make smart decisions and pick the .16pc Steak Knife and Bistecca Plate Set + 8" Chef's Knife + 3.5" Paring Knife Bundle How a Knife’s Rockwell Hardness is Measured Photo courtesy of Tec-Science. To determine a blade’s Rockwell Hardness, a diamond tip is pressed into the surface of a knife’s blade using minor force, forming an .

A high hardness value is most important for knives used for tough and extreme cutting, and durability will be an essential consideration for knives to be used for chopping. How to test hardness in knife making. The .The only test that can be done relatively simply is to assess the hardness of the steel, but this only provides an indication of how the material has been hardened. . a knife blade should be sent to the test laboratory at regular intervals for examination. If the straightness or flatness of the knife blades is found to need adjustment after . TIP: A Mohs hardness test is one of the most useful tricks that should be in all rockhounds’ playbooks. Check out the best test kits in the article below: . A common knife has a very similar hardness to glass. So, it can also be used to differentiate whether a mineral is softer or harder than 5. A steel file is harder (6-6.5) than a knife .

To my way of thinking, the first variable to consider is the constituent steels in the damascus. If it's simple carbon steels (1084, 1095, 15n20, etc) that won't create a barrier to diffusion of carbon in the matrix, and your HT is done properly, a standard rockwell test should provide useful information. The set goes 45, 50, 55, 60, and 65 RC. If one bites, and the next one down doesn't, then you are somewhere in between. After using them a little, you get a feel of about where the hardness is by the amount of bite you get. It helps if you have a few testing blocks of a known hardness.

The paper test is the most popular test for knife sharpness. To test your knife’s sharpness, take a piece of paper, place it between your fingers and draw the knife downwards. A sharp knife will slice the paper cleanly without you applying any force, while a dull blade will tear and rip at the paper, making for a messy cut.

Personally, I use the brass rod test on EVERY blade that goes out the door. It's not an indicator of any specific/exact hardness, but rather a test of the correct working hardness for the given steel, with the given edge geometry you've installed. Don't fall into the mindset of "harder is better"! It's not! How to use Rockwell Hardness Files for knife making. Testing files can be used as an affordable way to test the hardness of knife blades after heat treating.. If you want to identify a mineral, a hardness test can give you valuable information. You'll probably need to do a scratch test to in order to find what minerals are harder than your sample. Then, you can refer to the Mohs hardness scale, which ranks common minerals by hardness. . You can also use a pocket knife or rock hammer for this part .

rockwell steel hardness test

A must for most any machine shop! An easy-to-use, dramatically less expensive alternative to a Benchtop Hardness Tester, the TTC Hardness Tester File Set all.

The Rockwell hardness of knife steel determines how strong or hard the steel is. The rating shows how resistant the blade is to permanent deformation or penetration by another material. . Here is how the test calculates the hardness of steel: The steel is placed under an indenter with a starting force of 10 KGF. The depth caused by this force . In this advanced knife making tutorial, I discuss why knife makers should test the hardness of their blades and demonstrate how I use the Ames Model 1 to tes. Since I am new to Hardness testers, I wanted to make sure this is a good system for testing Knife Hardness. Does anyone know if this will do the job? I'm also open to other options for good quality testers. Last edited: Jun 18, 2019. Reactions: E.Carlson. J. Joker66. Gold Member. Joined Apr 20, 2014

I put the knife through a series of tests to show how durable and tough the blades can be.

How Hard Is Cheap Knife Steel? Hardness Testing Spyderco Tenacious 8cr13mov. I was definitely surprised by the results. Results are on the rockwell scale o. Rockwell hardness scale is the most common unit to identify knife steel hardness. When a knife’s hardness is between HRC 45 and the low-50s, we see it as being on the softer side. Any steel that’s higher than the mid-50s is seen as hard. However, once it goes beyond 60, that’s when we label it as very hard. http://www.envirosponsible.com/ Visit my site.IMPORTANT! Perform this test at your own risk! There are some who feel that performing this test can can d. For a typical knife, you want steel that is high in hardness, strength, toughness, edge retention, workability, sharpness, and preferably corrosion resistance. Generally, you don’t want steel with less than 0.6% of carbon. Chances are it won’t hold the edges very well and will dull quickly. Note that not all knives are made for the same .

Do a search for "tsubosan hardness files" It's a small collection of files that help measure varying grades of hardness. Effectively - you check to see if the file skates off or bites and scratches the surface. You want to get the blade down to bare metal before testing - no decarb layer. The files range from 40-65 HRC. The # will be different from knife to knife, but still specific to the knife going in the heat. I think you need to test your steels hardness to know if you got the HT where you wanted it. Especially the original poster.

This is a sleek desk top mineral testing kit. This is a unique set as the hardness points on the picks are not the actual minerals but alloys and metals made to replicate the hardness of the mohs scale. The set comes with four double sided testing picks from hardness two through nine. It also comes with a streak plate, glass plate, and a magnet.

In this blog, the team at Red Label Abrasives outlines the best ways to test the sharpness of a knife, as well as, how you can keep it in. Free Shipping over 0 (Excludes Oversized Products) Menu. Sanding Belts; Sanding Discs . The composition and hardness of the blade material determine how well it can be sharpened and how long the . Test HRC @ Home. Steel Hardness Testing On A Budget!!!HRC File Set - On Sale - https://amzn.to/3GgoroNGot to www.OCD4EDC.com for Awesome EDC Gear!HRC Testin.

rockwell knife hardness chart

This is something that many websites, blogs, and writers miss out on when discussing blades. They are all too focused on the properties of steel, and they overlook the balance, fit, finish, geometry, accessories, service, and design of a knife. Hardness. There are a lot of different things that can affect the hardness and toughness of a knife.

Assetto Corsa - The Real Race - Join The Competition Now!About the GameNEXT GENERATION RACING SIMULATORAssetto Corsa features an advanced DirectX 11 .

how to test knife hardness|rockwell knife hardness chart